Less' international-based offsets are derived from Gold Standard and Verified Carbon Standard (VCS) projects. These projects maximize positive environmental and social impact for the livelihood of communities.

Improved safe drinking water in Somali Regional State

This project installs solar powered safe drinking water systems in Somali Regional State, Ethiopia,

providing the local community of 5,800 access to clean drinking water. Each of the newly

constructed water supply systems includes a borehole from which water is extracted due to a

solar-power submersible pump and led to a storage tank.

This project installs solar powered safe drinking water systems in Somali Regional State, Ethiopia,

providing the local community of 5,800 access to clean drinking water. Each of the newly

constructed water supply systems includes a borehole from which water is extracted due to a

solar-power submersible pump and led to a storage tank.

Prior to this project, families would rely on burning firewood and boiling water inefficiently for their drinking and cleaning purposes. Through this offset project, carbon dioxide emissions are mitigated from the combustion process of burning wood, and health-impacts from contaminated water are avoided.

> See all project design documents and verification reports here.

Community Carbon Efficient Cooking Programme in Tanzania

This project distributes roughly 425,000 fuel-efficient cookstoves to rural households in Tanzania.

By replacing baseline cookstoves with ‘Smarthome Pro & Community Jiko Bora’ cookstoves, wood is

burned more effectively, reducing carbon dioxide emissions and other health hazards from indoor

smoke pollution.

This project distributes roughly 425,000 fuel-efficient cookstoves to rural households in Tanzania.

By replacing baseline cookstoves with ‘Smarthome Pro & Community Jiko Bora’ cookstoves, wood is

burned more effectively, reducing carbon dioxide emissions and other health hazards from indoor

smoke pollution.

The average annual emission reductions are more than 933,092 tCO2e.

> See all project design documents and verification reports here.

Previously supported projects:

Safe water access and improved cookstoves in Central Mozambique

This project increases access to clean drinking water by improving existing borehole technologies for rural communities in Tete, Sofala and Manica. Prior to this project, boreholes were poorly managed or proven too expensive to repair. Families would rely on burning firewood and boiling water on inefficient three stone fires for their drinking and cleaning water. Through this offset project, carbon dioxide emissions are mitigated from the combustion process of burning wood.

This project increases access to clean drinking water by improving existing borehole technologies for rural communities in Tete, Sofala and Manica. Prior to this project, boreholes were poorly managed or proven too expensive to repair. Families would rely on burning firewood and boiling water on inefficient three stone fires for their drinking and cleaning water. Through this offset project, carbon dioxide emissions are mitigated from the combustion process of burning wood.

A total of 2,042 boreholes were rehabilitated through this project and roughly 60,000 tonnes of CO2e are reduced annually.

> Project design document, validation and verification reports

Installation of high-efficiency wood burning cookstoves in Tanzania

This project distributes roughly 500,000 fuel-efficient cookstoves to rural households in Tanzania. By replacing baseline cookstoves with 'Rocket Stoves', wood is burned more effectively, reducing carbon dioxide emissions and other health hazards from indoor smoke pollution. Rocket Stoves are known for their high-insulation combustion chambers made from brick, clay and sand, which overall reduce heavy wood fuel use.

This project distributes roughly 500,000 fuel-efficient cookstoves to rural households in Tanzania. By replacing baseline cookstoves with 'Rocket Stoves', wood is burned more effectively, reducing carbon dioxide emissions and other health hazards from indoor smoke pollution. Rocket Stoves are known for their high-insulation combustion chambers made from brick, clay and sand, which overall reduce heavy wood fuel use.

The average annual emission reductions are more than 1,800,000 tCO2e.

> Project design document, validation and verification reports

New featured project: Taishan Geothermal Central Heating System

Located in Taishan Village in China's Henan province, this geothermal project heats residential and commercial buildings in the winter. The use of renewable geothermal energy reduces the region's reliance on coal-fired boilers, avoiding emissions that contribute to climate change and improving air quality.

Located in Taishan Village in China's Henan province, this geothermal project heats residential and commercial buildings in the winter. The use of renewable geothermal energy reduces the region's reliance on coal-fired boilers, avoiding emissions that contribute to climate change and improving air quality.

The Taishan Geothermal Central Heating System has a total heating load of 116.84 MW. This project also targets multiple Sustainable Development Goals (SDGs), including Affordable and Clean Energy, Decent Work and Economic Growth, and Climate Action.

> Project design document, validation and verification reports

Safe Drinking Water Project in Uganda

This project distributes ceramic water filters to more than 200 communities across Uganda, providing accessible and safe drinking water to low-income households and public spaces like schools and clinics. Recipients can use filters instead of burning wood to boil water for drinking, which reduces greenhouse gas emissions and smoke that can lead to respiratory diseases.

This project distributes ceramic water filters to more than 200 communities across Uganda, providing accessible and safe drinking water to low-income households and public spaces like schools and clinics. Recipients can use filters instead of burning wood to boil water for drinking, which reduces greenhouse gas emissions and smoke that can lead to respiratory diseases.

Ceramic water filters are chemical-free, low-maintenance, and effective. They’re also in line with the traditional Ugandan way of storing water in clay pots. Additionally, the project creates job opportunities for local people who produce and deliver the filters.

> Project design document, validation and verification reports

Solar Cooker Project in Zhenping County, China

This project distributes 50,000 solar cookers to rural households in Zhenping County, Henan Province. Most rural households in Zhenping use coal-fired stoves for boiling water and cooking, generating greenhouse gas emissions and air pollutants. Replacing coal-fired stoves with solar cookers reduces emissions that contribute to climate change and improves air quality.

This project distributes 50,000 solar cookers to rural households in Zhenping County, Henan Province. Most rural households in Zhenping use coal-fired stoves for boiling water and cooking, generating greenhouse gas emissions and air pollutants. Replacing coal-fired stoves with solar cookers reduces emissions that contribute to climate change and improves air quality.

The rated power of each solar cooker is 894.6Wth, and the total capacity of the project is 44.73MWth. This project is estimated to reduce emissions by 109,294 tCO2e annually.

> Project design document, validation and verification reports

Featured project: SusGlobal Belleville Composting Offset Project

Located in Roslin, Ontario, the SusGlobal Belleville Composting Project converts organic waste into nutrient-rich grade A composting soil by using Gore System technology. Using a three-phase approach, this method regulates the temperature, moisture, and aeration of the compost over the span of six to eight weeks.

Located in Roslin, Ontario, the SusGlobal Belleville Composting Project converts organic waste into nutrient-rich grade A composting soil by using Gore System technology. Using a three-phase approach, this method regulates the temperature, moisture, and aeration of the compost over the span of six to eight weeks.

This waste management facility accepts approximately 44 tonnes of sewage biosolids and 385 tonnes of Source Separated Organics (SSO) per week, including materials from other composting facilities, yard and leaf waste, and other small waste sources. This facility reduces methane emissions by aerobically digesting organic waste instead of letting it go to landfill.

> Project design document, validation and verification reports

Featured project: Slag-based recycling operations by Les Minéraux Harsco in Quebec

This project quantifies the greenhouse gas (GHG) emissions reductions from slag-based recycling plants in Contrecoeur and Sorel-Tracy, Quebec. The plants recover and recycle slags and other residues from the metal industry, which can then be used in new products.

This project quantifies the greenhouse gas (GHG) emissions reductions from slag-based recycling plants in Contrecoeur and Sorel-Tracy, Quebec. The plants recover and recycle slags and other residues from the metal industry, which can then be used in new products.

Harsco’s method of recycling manufacturing waste is less GHG-intensive than typical scrap metal recycling. Project benefits also include minimizing the use of virgin material in new products and diverting manufacturing waste from landfill.

> Project design document, validation and verification reports

Composting Facility in Abbotsford, British Columbia

The Net Zero Waste Inc. City of Abbotsford Composting Facility is an aerobic composting project located in Abbotsford, British Columbia. The facility processes residential food and yard waste, commercial waste, and agricultural waste from the City of Abbotsford and the surrounding region.

The Net Zero Waste Inc. City of Abbotsford Composting Facility is an aerobic composting project located in Abbotsford, British Columbia. The facility processes residential food and yard waste, commercial waste, and agricultural waste from the City of Abbotsford and the surrounding region.

Without a composting facility, this waste would have decomposed anaerobically in a landfill, releasing harmful methane emissions. Methane contributes to climate change and is 28 times more potent than carbon dioxide over a 100-year period.

> Project design document, validation and verification reports

Landfill Gas Extraction and Electricity Generation Project in Istanbul, Turkey

This project captures landfill gas from two sites in Istanbul and uses it to generate electricity. In the absence of this project, waste would decay openly in the landfills and emit methane, a potent greenhouse gas, into the atmosphere.

This project captures landfill gas from two sites in Istanbul and uses it to generate electricity. In the absence of this project, waste would decay openly in the landfills and emit methane, a potent greenhouse gas, into the atmosphere.

The electricity this project generates displaces electricity from power plants connected to the Turkish grid, which are primarily fossil fuel based. The project also improves odours and air quality surrounding the landfill sites.

> Project design document, validation and verification reports

Featured project: Essex-Windsor Regional Landfill Gas Capture and Destruction

The Essex-Windsor Regional Landfill Gas Capture and Destruction Project is designed to collect landfill gas from twenty-three vertical wells spread throughout the closed landfill cells.

The Essex-Windsor Regional Landfill Gas Capture and Destruction Project is designed to collect landfill gas from twenty-three vertical wells spread throughout the closed landfill cells.

The plant is equipped with a fan blower that provides vacuum to the wellfield in order to draw landfill gas from the waste to the plant. The blower conveys landfill gas to a flare where the gas is ignited and burned continuously in an enclosed flare.

Prior to the implementation of the project, there were no collection and destruction facilities at the site. LFG was vented to the atmosphere.

> Project design document, validation and verification reports

Featured project: Vietstar Municipal Solid Waste Treatment Plant in Vietnam

This facility captures methane gas emissions from municipal waste and converts organic materials into sustainable compost for local farmers. The project involves pre-sorting and classifying municipal solid waste, recycling plastic, and treating organic matter with LEMNA composting technology. Prior to this initiative, improper disposal of waste led to organic materials decaying openly in landfill and releasing methane emissions into the atmosphere.

This facility captures methane gas emissions from municipal waste and converts organic materials into sustainable compost for local farmers. The project involves pre-sorting and classifying municipal solid waste, recycling plastic, and treating organic matter with LEMNA composting technology. Prior to this initiative, improper disposal of waste led to organic materials decaying openly in landfill and releasing methane emissions into the atmosphere.

The project treats approximately 400,000 tonnes of solid waste per year, and it has boosted the local economy by creating 810 jobs. The waste treatment plant is expected to produce 53,568 tonnes of organic compost annually, and prevent 182,000 tonnes of CO2e from entering the atmosphere on average each year.

> Project design document, validation and verification reports

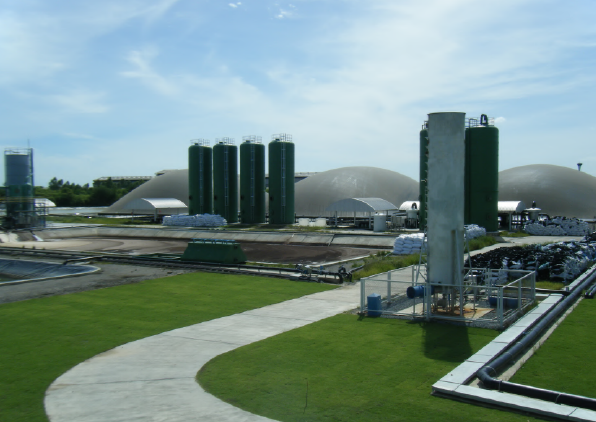

Featured project: San Miguel Biogas Project in Thailand

Located in Amphor Tha Muang, Thailand, the San Miguel Biogas project captures biogas from wastewater from the Thai San Miguel Liquor distillery (TSML), and converts it into electricity. From alcohol and spirits production, the TSML distillery produces large amounts of wastewater with high organic matter content. Before this project was implemented, the wastewater released methane into the atmosphere.

Located in Amphor Tha Muang, Thailand, the San Miguel Biogas project captures biogas from wastewater from the Thai San Miguel Liquor distillery (TSML), and converts it into electricity. From alcohol and spirits production, the TSML distillery produces large amounts of wastewater with high organic matter content. Before this project was implemented, the wastewater released methane into the atmosphere.

By installing a digester between the exiting sump pit and the lagoons, an estimated 30,000 m3 of biogas is captured from the wastewater and is then used for heat generation for the distillery boilers, as well as electricity generation, which is exported to the Thai national electricity grid. The project mitigates close to 87,990 tonnes of CO2e per year.

> Project design document, validation and verification reports

Chlorine dispensers in Eastern Uganda

This chlorine dispenser program provides rural communities in Eastern Uganda with safe sources of drinking water. Chlorine dispensers replace the need to boil water with wood-burned fire, thereby reducing greenhouse gas emissions, preventing deforestation and improving indoor air quality. To date, the project has mitigated more than 170,000 tonnes of carbon dioxide emissions from the environment. The dispenser program also improves quality of life by reducing water-borne diseases; educating villagers about the dangers of contaminated water; and saving resources that would have been spent gathering wood or purchasing fuel to boil water.

This chlorine dispenser program provides rural communities in Eastern Uganda with safe sources of drinking water. Chlorine dispensers replace the need to boil water with wood-burned fire, thereby reducing greenhouse gas emissions, preventing deforestation and improving indoor air quality. To date, the project has mitigated more than 170,000 tonnes of carbon dioxide emissions from the environment. The dispenser program also improves quality of life by reducing water-borne diseases; educating villagers about the dangers of contaminated water; and saving resources that would have been spent gathering wood or purchasing fuel to boil water.

> Project design document, validation and verification reports

> Video profile of project

FRSWC's Landfill Gas Management System

Fredericton Region Solid Waste Commission's (FRSWC) Landfill Gas Management System (LGMS) is designed to significantly reduce greenhouse gases created by landfill waste. The FRSWC collects between 75,000 and 80,000 tonnes of garbage annually. By voluntarily capturing and flaring the landfill gas emitted by the waste, the LGMS is able to eliminate approximately 45,000 tonnes of CO2 equivalent from the atmosphere each year—emissions that would have otherwise been released into the atmosphere. The project helps to create local jobs: there are more than 50 employees at the FRSWC site on Alison Blvd in Fredericton.

Fredericton Region Solid Waste Commission's (FRSWC) Landfill Gas Management System (LGMS) is designed to significantly reduce greenhouse gases created by landfill waste. The FRSWC collects between 75,000 and 80,000 tonnes of garbage annually. By voluntarily capturing and flaring the landfill gas emitted by the waste, the LGMS is able to eliminate approximately 45,000 tonnes of CO2 equivalent from the atmosphere each year—emissions that would have otherwise been released into the atmosphere. The project helps to create local jobs: there are more than 50 employees at the FRSWC site on Alison Blvd in Fredericton.

> Project design document, validation and verification reports

Featured project: Nakhon biogas wastewater treatment plant in Thailand

This biogas project captures methane from wastewater produced by a Thai starch plant and uses the methane to generate renewable electricity for the facility. The project mitigates 100,000 tonnes of carbon dioxide emissions annually. The methane capture project and resulting carbon revenues help create jobs, while supporting social and educational activities in the community. In addition, the clean wastewater is used to irrigate nearby fields, enabling the community to farm fish as an additional source of income.

This biogas project captures methane from wastewater produced by a Thai starch plant and uses the methane to generate renewable electricity for the facility. The project mitigates 100,000 tonnes of carbon dioxide emissions annually. The methane capture project and resulting carbon revenues help create jobs, while supporting social and educational activities in the community. In addition, the clean wastewater is used to irrigate nearby fields, enabling the community to farm fish as an additional source of income.

> Project design document, validation and verification reports

> Methodology

Featured project: Solar Cooker project in Nanyang Danjiang River Region, China

The Nanyang Danjiang Solar Cooker Project enables these rural households to substitute traditional coal stoves for a solar energy alternative. 48,000 of these stoves have been distributed to seven towns in the Xichuan County, Henan Province. They are 50% more efficient than traditional coal stoves and, with an energy capacity of 876.5 W per unit, displace the CO2 that would have been generated by the fossil fuel consumption of coal fires. By switching to solar power, health issues related to the excess soot and indoor smoke-pollution of coal fires have been abated. The solar cookers are distributed and maintained by the project for free, and because they no longer have to purchase coal fuel, villagers can use the money saved to buy things that improve their standard of living.

The Nanyang Danjiang Solar Cooker Project enables these rural households to substitute traditional coal stoves for a solar energy alternative. 48,000 of these stoves have been distributed to seven towns in the Xichuan County, Henan Province. They are 50% more efficient than traditional coal stoves and, with an energy capacity of 876.5 W per unit, displace the CO2 that would have been generated by the fossil fuel consumption of coal fires. By switching to solar power, health issues related to the excess soot and indoor smoke-pollution of coal fires have been abated. The solar cookers are distributed and maintained by the project for free, and because they no longer have to purchase coal fuel, villagers can use the money saved to buy things that improve their standard of living.

> Project design document, validation and verification reports